Australia Watanabe Stone Crusher THOR – 3.0+ KIT DRAWBAR

The Australia Watanabe Stone Crusher THOR – 3.0+ KIT DRAWBAR is a heavy-duty crushing machine designed for large-scale agricultural and construction projects. With a 230-horsepower tractor requirement, it is compatible with Category 2 linkage systems, fitting tractors from brands like John Deere, Case IH, and New Holland. The THOR 3.0+ is ideal for land clearing, rock removal, and road construction, offering a 3.0-meter working width and reliable performance in demanding conditions. With its robust design and advanced hydraulic control, it delivers efficient and stable operation on tough materials in quarries and large-scale farms.

Product Parameters

| TECHNICAL DATA | THOR 3.0 |

|---|---|

| Dimensions | |

| Length (mm.) | 1732 |

| Width (mm.) | 3000 |

| Height (mm.) | 1212 |

| Weight | 2800 Kg |

| Bottom linkage category | 2 |

| Width | 3.0 m |

| Tractor requirements | |

| Engine power (min.) | 230 cv |

| Working speed | 3 Km/h |

| Required control valves | 2 |

Product Overview

The Watanabe THOR 3.0 stone crusher is a high-performance, heavy-duty machine designed for large-scale rock and stone crushing operations. Its robust construction and unique design make it an ideal choice for use in quarries, mines, and large-scale construction projects. The THOR 3.0 model incorporates advanced technology to ensure superior crushing efficiency and reliability.

The key specifications of the THOR 3.0 include a length of 1732mm, a width of 3000mm, and a height of 1212mm, with a total weight of 2800 kg. These dimensions and weight allow the machine to perform effectively in challenging job sites, providing consistent and reliable performance even during high-demand tasks.

Equipped with a 230-horsepower engine, the THOR 3.0 operates at a working speed of 3 km/h, delivering powerful output to meet demanding workloads. The machine's two control valves and hydraulic system offer precise control, ensuring optimal stability and functionality in various environments.

Technical Advantages of the Watanabe THOR 3.0 Stone Crusher

Exceptional Structural Design and Size

The Watanabe THOR 3.0 stone crusher is engineered with a robust design that guarantees efficient and stable operation in harsh working conditions. With its dimensions of 1732mm in length, 3000mm in width, and 1212mm in height, and a weight of 2800 kg, it is perfectly suited for heavy-duty applications in quarries and mining operations. The large size not only offers increased capacity but also enhances the machine's stability, making it ideal for high-intensity crushing tasks.

High Power and Performance

The THOR 3.0 is powered by a 230-horsepower engine, ensuring excellent performance during large-scale stone crushing operations. Operating at a speed of 3 km/h, this machine efficiently handles long-duration tasks while maintaining high productivity. Compared to similar machines, the THOR 3.0 excels in power delivery and crushing capacity, making it a reliable choice for high-demand environments.

High Load Capacity and Stability

The THOR 3.0 is built to withstand long hours of heavy-duty use, with a weight of 2800 kg and a Category 2 linkage. This combination ensures the machine remains stable even during intense operations. Whether in mining, quarrying, or road construction, the THOR 3.0 maintains superior performance under challenging conditions, providing long-lasting reliability and efficiency.

Applications of the Watanabe THOR 3.0 Stone Crusher

Heavy-Duty Mining and Stone Crushing

The Watanabe THOR 3.0 is ideally suited for heavy-duty stone crushing applications in mining and quarrying operations. It efficiently handles tough rocks and ores, providing excellent crushing performance. Its powerful engine and advanced features allow it to manage large-scale stone crushing tasks, increasing productivity and operational efficiency.

Construction Sites and Road Building

Stone crushers are crucial for construction sites and road building projects. The THOR 3.0 can process a variety of materials, including large stone blocks and concrete rubble, ensuring smooth project progression. Whether for large infrastructure projects or smaller road construction tasks, the THOR 3.0 delivers powerful support for efficient material processing.

Core Components Analysis: Ensuring Long-Term Stable Operation

High-Performance Engine System

The Watanabe THOR 3.0 stone crusher is equipped with a 230-horsepower high-efficiency engine that ensures consistent and powerful performance even under heavy-duty conditions. The engine is designed to offer low fuel consumption and high efficiency, helping to reduce operational costs while maintaining peak performance. In various working environments, this powerful engine supports the machine’s ability to run continuously and efficiently, adapting well to demanding tasks.

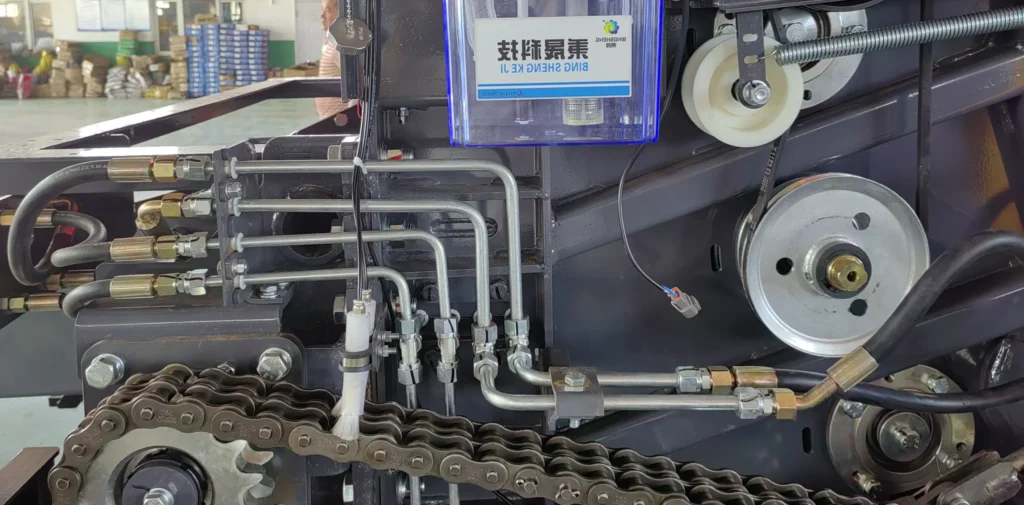

Precise Control Valves and Hydraulic System

The THOR 3.0 features an advanced hydraulic system with two control valves, providing precise control during operation. This design enhances the machine’s responsiveness, allowing for real-time adjustments in crushing force and operational speed. The hydraulic system’s efficiency minimizes maintenance downtime and improves overall productivity, ensuring that the machine delivers consistent performance throughout its service life.

Reinforced Crushing Blades and Wear-Resistant Components

To withstand prolonged heavy-duty operations, the THOR 3.0 is equipped with high-strength, wear-resistant crushing blades and critical components. These parts are designed to reduce wear and extend the machine's lifespan. Whether dealing with high-hardness materials or operating in harsh environments, the THOR 3.0 maintains its performance and efficiency, lowering maintenance costs and the need for frequent part replacements.

Maintenance and Care

Regular Inspections and Maintenance

To ensure the Watanabe THOR 3.0 operates at its best over the long term, regular inspections and maintenance are essential. It is recommended that users perform periodic checks on critical components such as the engine, hydraulic system, and crushing blades. Timely maintenance helps identify potential issues early, minimizing the risk of unexpected breakdowns and ensuring the equipment runs smoothly and efficiently.

Reliable After-Sales Service and Support

Watanabe offers comprehensive after-sales service for the THOR 3.0, including routine inspections, technical support, and troubleshooting. All customers who purchase the THOR 3.0 are entitled to a one-year warranty, which covers any quality issues. In case of problems, Watanabe provides quick responses and repair services to minimize downtime. Additionally, global after-sales support ensures that customers can access help whenever and wherever they need it.

Genuine Spare Parts and Technical Support

To maintain the THOR 3.0’s peak performance, Watanabe provides genuine spare parts and comprehensive technical support. All parts are OEM (Original Equipment Manufacturer) quality, ensuring optimal compatibility and durability. Whether it’s replacing the crushing blades, hydraulic components, or engine maintenance, we offer expert guidance to help users maintain the machine’s efficiency and extend its operational life.

Efficient Stone Crushing Solutions for the Australian Market

As a local Australian company, we understand the critical role mining and infrastructure construction play in our economy. The Watanabe THOR 3.0 stone crusher is designed to meet this challenge, delivering outstanding performance in Australia’s unique and demanding conditions. Whether it's vast mining operations or busy road construction projects, the THOR 3.0, with its powerful engine and efficient crushing capabilities, helps our clients boost productivity and ensure smooth operations. We’ve tailored the THOR 3.0 to meet the specific needs of the Australian market, offering high stability and durability to maintain peak performance during extended heavy-duty use. As a local supplier, we’ve built strong relationships with our customers, ensuring timely after-sales service and technical support, keeping your equipment in optimal condition, reducing operating costs, and enhancing overall project efficiency.

Why Choose Us?

Proven Track Record in Tough Conditions

We've been building reliable stone crushers for agricultural and construction work since 2005, with a focus on heavy-duty gear that handles Australia’s basalt, ironstone, and bluestone without drama. Over 40 units are already out there—from North Queensland to the WA Wheatbelt—crushing rocks up to 600 mm and saving operators heaps on site prep.

Quality Built for the Long Haul

Our crushers are manufactured in our modern 5,000 m² facility in China using high-grade carbide teeth and reinforced frames tested for 800+ hours in real rock. Simple, low-maintenance design means easy tooth changes and minimal downtime on your job.

Fast Parts & Straight-Up Support for Australia

We keep common wear parts in stock in Perth so you’re never waiting weeks for teeth or bearings. Any questions or need a quote? Just drop us an email at [email protected] – we usually reply within a few hours, even on weekends.

Solid Warranty and No-BS Service

Every THOR series crusher comes with a 12-month parts warranty and 90-day labour cover through our Perth agent. Genuine spares, clear advice, and machines that keep earning you money season after season.

Your Partner in Smarter Crushing

We’re straight shooters: Chinese-built, field-proven, and priced right for Aussie conditions. Ready to get more done with less hassle? Email [email protected] today for current pricing and delivery times.

Get in Touch

Contact us today to discover how the Watanabe THOR 3.0 can elevate your projects!

FAQ

What tractor horsepower do I need to run the THOR 3.0?

Minimum 230 HP, but most Australian users run it comfortably on 250–350 HP tractors (John Deere 8R, Case IH Magnum, New Holland T8, Fendt 900, etc.). In tough basalt or ironstone country, 280+ HP makes life a lot easier.

How fast does it actually work on real jobs?

Typical forward speed is 1.5–3.5 km/h. Most operators sit around 2–2.5 km/h at 1000–1200 rpm when burying rocks 150–200 mm in one pass. You can push 3+ km/h in lighter country or when just skimming the surface.

What warranty do you offer in Australia?

12 months parts warranty + 90 days labour through our Perth-based spare parts agent. Wear parts (teeth, bolts, bearings) are stocked in Western Australia and shipped overnight to most areas.

What size rocks can it handle?

Up to 500–600 mm no problem. Machines currently working on basalt, bluestone, granite, ironstone, sandstone, and old concrete/railway ballast across QLD, NSW, VIC & WA.

How long do the teeth last?

Average Australian conditions: • Basalt/ironstone: 400–800 hours per set • Sandstone/lighter rock: 1000–1500+ hours Genuine carbide teeth kept in Perth stock – next-day delivery to most farms.

Customer Reviews

⭐⭐⭐⭐⭐ Jake Morrison, Owner-Operator, Morrison Civil, Sunshine Coast QLD Picked up the THOR 3.0 with the drawbar kit in March. Been feeding it straight basalt off a 30-tonner on a road job and it just keeps chewing. Size comes out perfect for GAB, so we’re skipping the screen altogether. Driver reckons it’s smoother than the old MB we had. Still on the first set of teeth after 600 hours. Bloody happy.

⭐⭐⭐⭐ Tommo (Lachlan Thompson), Foreman, BMD, Western Sydney Running it on a 336 Cat doing bulk earthworks out west. Does the job, no drama. Drawbar kit is handy when we’re jumping between pads – saves hooking up the dolly every five minutes. Only whinge is the weight; the 3.0 is a heavy bugger once it’s full, so you feel it on a 30-tonner when you swing fast. Four stars, solid unit.

⭐⭐⭐⭐⭐ Rach Kennedy, Quarry Supervisor, Holcim Geelong VIC We bought it for recycling old concrete stockpiles. Turns 600 mm slabs into 75 mm minus in one pass, no worries. The drawbar lets us drag a full bucket over to the stockpile without changing attachments – saves heaps of time. Been flat out six days a week for four months and nothing’s still going strong. Worth the coin.

⭐⭐⭐⭐ Dylan “Diz” Pearce, Plant Manager, Delta Group, Melbourne Got two of them now. One’s on hire in Gippsland chewing blue stone – teeth wear is normal for that rock. The other’s doing demo concrete in the last six weeks and it’s loving it. Quick couplers leaked a bit when new, just needed a nip-up. Drawbar kit is handy but the paint scratches easy. Decent gear, four and a bit stars.

⭐⭐⭐⭐⭐ Shane Burrows, Contractor, Burrows Excavations, Townsville Townsville heat is brutal and everything rusts quick. The THOR 3.0 has been here five months and still looks near new. Smashed through a pile of railway sleepers and concrete last week without missing a beat. Mate who runs a competitor brand came past, had a look and just said “yeah… might have to get one of these”. That says it all.