Australia Watanabe Potato Digger 2 Rows – Trailed

The Australia Watanabe Potato Digger 2 Rows – Trailed is a high-efficiency harvesting solution for large-scale potato farming. With a 2-row design, it increases productivity and reduces manual labor. Compatible with tractors requiring a minimum of 95 hp and 540 RPM PTO, this digger works efficiently on loamy and moderately clayey soils. The AWB-1600 series (AAR, BAR, CAR models) offers reliable, cost-effective options for various terrains. Designed for use with standard agricultural machinery, it ensures seamless compatibility with most tractors. Ideal for large potato farms or cooperatives, the Watanabe Potato Digger delivers high-quality, efficient harvesting, reducing operational costs and boosting productivity.

Product Parameters

| TECHNICAL DATA</ | AWB-1600 AAR</ | AWB-1600 BAR</ | AWB-1600 CAR</ |

|---|---|---|---|

| Weight | 1150 Kg | 1350 Kg | 1500 Kg |

| Number Rows | 2 | ||

| Tractor requirements | |||

| Engine power (min.) | 95 cv | 95 cv | 95 cv |

| Input speed p.t.o.-shaft | 540 RPM | 540 RPM | 540 RPM |

| Required control valves | - | 2 | 2 |

| Working speed | 5 - 10 Km/h | ||

Product Overview

The Australia Watanabe Potato Digger 2 Rows – Trailed is a high-efficiency potato harvesting machine designed specifically for large-scale agricultural production. It connects to a tractor via a trailing attachment, allowing for the completion of large-scale potato harvesting tasks in a shorter time frame, significantly improving operational efficiency. Built with high-strength materials and advanced technology, this machine ensures long-lasting, efficient performance. Whether for large farms or agricultural cooperatives, this potato digger provides an ideal solution for modern farming needs.

Compared to traditional manual harvesting methods, the Watanabe potato digger stands out in reducing labor costs and boosting operational efficiency. Its dual-row operation not only increases working speed but also minimizes soil disturbance, preserving the integrity of the potatoes and preventing extensive soil loss.

This machine is perfect for large-scale potato farming, saving labor costs while improving the overall quality of the harvest. It works efficiently across various soil types, particularly in loamy and moderately clayey conditions.

Technical Specifications

The Australia Watanabe Potato Digger 2 Rows – Trailed is equipped with technical specifications designed to meet modern agricultural requirements, ensuring efficient and reliable operation.

-

Weight: 1150 Kg – 1500 Kg, ensuring stability and durability, suitable for a wide range of terrains.

-

Working Speed: 5 – 10 km/h, adjustable depending on soil conditions and operational needs to ensure maximum efficiency in each task.

-

Minimum Engine Power Requirement: 95 cv, making it compatible with most standard agricultural tractors and reducing the equipment usage threshold.

-

Input Speed: 540 RPM, compatible with standard PTO systems to ensure effective power transmission.

-

Number of Rows: 2-row design for large-scale, high-efficiency harvesting, reducing redundant operations and maximizing land use.

-

Control Valve Requirement: 2, meeting the standard requirements for most agricultural machinery, making it easy to operate.

-

Soil Adaptability: Ideal for loamy and mildly clayey soil, performing optimally across most common soil types.

This machine not only raises the level of agricultural mechanization but also streamlines operations, making it a perfect solution for farms of all sizes and helping users boost productivity.

Advantages of Potato Digger

The Australia Watanabe Potato Digger 2 Rows – Trailed is designed with a focus on boosting efficiency and lowering operational costs, making it the ideal choice for modern farms and agricultural cooperatives.

High Efficiency: The dual-row design increases the area covered per hour, reducing the time needed for each task. For example, it can cover larger areas of land each hour, significantly enhancing harvest speed.

Cost-Effective: Compared to traditional manual harvesting and other potato harvesters, the Watanabe model consumes less fuel and has lower operational costs, making it a great long-term investment.

Durability: Built with high-strength alloys and precision-engineered transmission systems, this machine ensures stable performance in demanding work environments, extending its service life and reducing the need for frequent repairs.

Reduced Crop Damage: The harvesting process is designed to minimize potato damage, maintaining a higher percentage of whole crops, which ultimately improves the quality of the final yield.

Versatile Soil Adaptability: This machine performs exceptionally well in loamy and moderately clayey soils, ensuring efficient harvesting even in less-than-ideal soil conditions.

With these advantages, the potato digger is a key piece of equipment for enhancing agricultural productivity, reducing costs, and improving farm operations.

How It Works

The Australia Watanabe Potato Digger 2 Rows – Trailed operates using advanced soil loosening and material conveyance technology. It connects to a tractor via the PTO shaft, and is powered by the tractor’s engine, driving the digging mechanism.

-

Soil Loosening: As the machine moves across the land, specially designed blades and vibration systems loosen the soil, effectively extracting the potatoes from the ground. This process ensures minimal soil and crop disturbance, reducing soil loss and crop damage.

-

Material Conveyance: Once the potatoes are loosened, they are automatically transported via a conveyor system to the front collection area, eliminating the need for manual handling and additional operations, greatly improving operational efficiency.

-

Minimized Land Disruption: The dual-row design allows the machine to harvest two rows of potatoes at once, reducing soil disturbance and ensuring the potatoes remain intact. This not only increases harvesting speed but also protects the soil structure, reducing difficulties in subsequent planting.

The Watanabe potato digger’s operational system is simple and efficient, suitable for farms of all sizes and various land conditions, making it a great choice for modern agricultural mechanization.

Applications

The Australia Watanabe Potato Digger 2 Rows – Trailed is a versatile piece of equipment designed to meet the needs of various agricultural operations, particularly those focused on large-scale potato farming.

Large-Scale Potato Farms: This potato digger is perfect for farms with expansive potato fields. Its dual-row design allows for efficient and rapid harvesting, ensuring high productivity on large-scale operations.

Agricultural Cooperatives: For agricultural cooperatives, this machine offers a reliable and efficient solution to handle the collective needs of multiple farms, increasing operational efficiency and reducing costs across the board.

Farmers Transitioning to Mechanization: For farms transitioning from manual labor to more mechanized processes, the Watanabe potato digger is an ideal starting point. It boosts productivity while reducing reliance on seasonal labor.

Labor-Saving Technology: The machine's ability to reduce manual labor is especially valuable in regions facing labor shortages. It ensures that harvesting is done quickly and efficiently, saving valuable time and money.

Diverse Soil Conditions: The digger works effectively across various soil types, from loamy to moderately clayey soils, providing an adaptable solution for different environmental conditions.

Overall, the Watanabe potato digger is designed to meet the needs of farmers looking to increase productivity, reduce labor costs, and ensure a more efficient and sustainable potato harvesting process.

Maintenance and Care

To ensure the long-term reliability and performance of the Australia Watanabe Potato Digger 2 Rows – Trailed, regular maintenance is crucial. By following proper maintenance procedures, users can extend the machine's lifespan and reduce downtime.

- Routine Inspections: After every 300 hours of operation, perform a thorough inspection of the machine, particularly the transmission system and power systems, to identify any unusual noises or wear.

- Lubrication: Regular lubrication of moving parts is essential to prevent excessive wear and tear. Use high-quality lubricants and follow the recommended maintenance schedule, typically every 1500 hours.

- Cleaning: After each use, thoroughly clean the equipment, removing soil, debris, and residues from the digging and conveyor systems. This prevents build-up that could impair performance and reduce efficiency.

- Hydraulic Systems: Check the hydraulic systems regularly for leaks or signs of damage, as these systems are crucial for smooth operation.

- Troubleshooting: In the event of malfunction or breakdown, consult the user manual for basic troubleshooting. If necessary, contact the support team for more detailed assistance.

Following these maintenance guidelines will ensure that the Watanabe potato digger continues to operate at peak performance, minimizing the risk of failure during the harvesting season.

How to Choose the Right Model

Choosing the right model of the Australia Watanabe Potato Digger 2 Rows – Trailed depends on several factors that align with your farming needs. The machine comes in different configurations, and selecting the appropriate one will ensure you achieve the best results for your operation.

-

Farm Size and Harvesting Volume: For larger farms with extensive potato fields, the heavier models with higher power requirements are ideal. These models can handle larger volumes and are designed for continuous, high-efficiency work.

-

Tractor Compatibility: Ensure that your tractor meets the minimum power requirements (95 cv). A tractor with too little power can affect the performance of the digger, leading to slower harvesting speeds.

-

Soil Type: If your farm has heavier, clay-based soil, consider a model designed to handle such conditions. The digger performs best in loamy and moderately clayey soils, so understanding your soil type is crucial in choosing the right model.

-

Budget Considerations: While the larger, more powerful models provide higher productivity, they may come with a higher initial cost. Assess your budget and expected ROI to choose the best option for your financial situation.

-

Operational Needs: Consider the specific demands of your farming operation. If you need to cover large areas quickly, a model with a higher work rate may be beneficial. For smaller, more specialized farms, a compact model might be more suitable.

By understanding your operational requirements, farm size, and budget, you can select the Watanabe potato digger model that will best suit your needs and help maximize your harvest efficiency.

Replacement of Wearable Parts:

Like any agricultural machine, certain parts of the AWB-1600 are subject to regular wear. The digging blades, chains, and hydraulic components may need replacement after extensive use. Timely replacement of these parts ensures that the machine maintains its efficiency and doesn’t cause unnecessary delays during harvest.

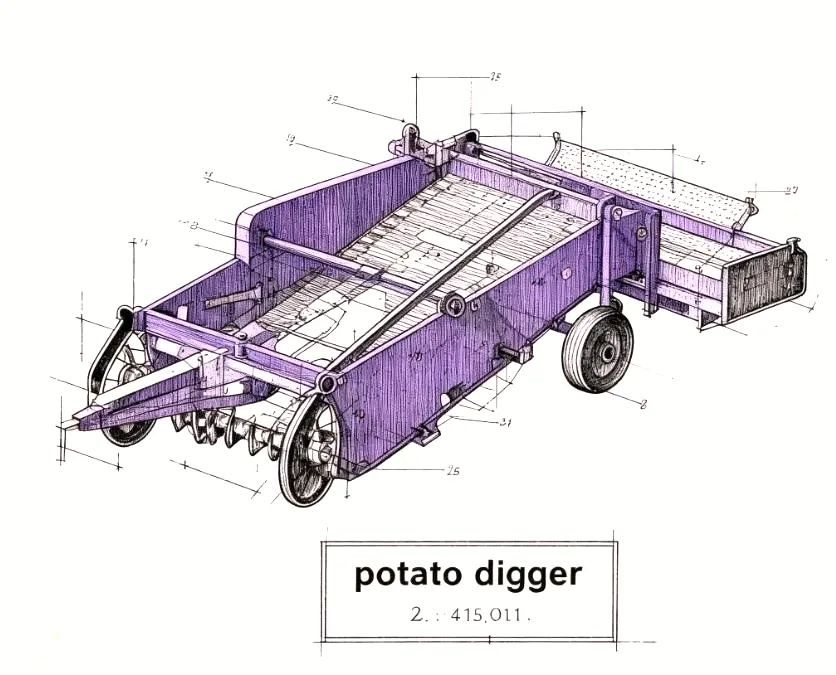

Core Components

The core components of the AWB-1600 Potato Digger are made with high-quality materials and advanced designs to ensure stable and efficient operation under various working conditions. Below are the key components and their functions:

Gearbox:

The AWB-1600 is equipped with a high-performance gearbox that transfers power efficiently, ensuring smooth operation of the machine. The precise design of the gearbox allows the digger to perform effectively under varying loads and working conditions, providing ample power to carry out the digging tasks. Whether working in soft or hard soil, the gearbox ensures a consistent and stable power output.

PTO Shaft (Power Take-Off Shaft):

The PTO shaft is the critical link between the AWB-1600 and the tractor, providing the necessary power for the machine’s operation. By utilizing the PTO shaft, the AWB-1600 draws power from the tractor to drive its digging and transmission systems. The high-efficiency design of the PTO shaft ensures stable power delivery even during high-load and long-duration operations, maintaining consistent work performance.

Hydraulic System:

The AWB-1600 features a powerful hydraulic system that controls the digging depth, adjusts the working modes, and provides precise operational control. The stability of the hydraulic system is essential for the machine’s high efficiency, allowing it to adapt to various soil types and ensuring accurate potato harvesting.

Transmission System:

The transmission system of the AWB-1600 is designed for efficiency, smoothly transferring power to various working components of the digger. This system ensures the machine operates seamlessly, with the ability to adjust working speeds based on different harvesting needs, providing greater flexibility.

Digging Blades:

The digging blades are made of high-strength, wear-resistant materials, ensuring long-term durability and stability. Designed for efficient potato digging, these blades minimize damage to the potatoes, ensuring a high-quality harvest.

These core components are meticulously designed and manufactured to ensure the AWB-1600 performs exceptionally well, maintaining high efficiency and stability even in challenging agricultural environments.

Contact us today to learn how our reliable machinery can boost your farm’s productivity!

Why Choose Us?

We've been reliably smashing rocks across Australia since 2005, from the fiery red soils of North Queensland all the way to the brutal ironstone country of the Wheatbelt. More than 40 of our machines are out there right now, happily chewing through basalt, bluestone and everything in between up to 600 mm without breaking a sweat. Farmers and contractors keep telling us the same thing: finally a crusher that actually saves fuel, time and sanity instead of adding extra headaches to the job. Every unit is built in our modern 5,000 m² factory in China using proper high-grade carbide teeth and seriously reinforced frames that we hammer for over 800 hours on real Aussie rock before they ever leave the line. Fewer moving parts means way less to go wrong, and swapping a tooth is a ten-minute job with nothing more than basic spanners—no need for a full workshop or a PhD. We stock all the high-wear bits (teeth, bearings, seals, the lot) right here in Perth, so you’re back crushing in days, not months, and when you call or email you’ll actually speak to someone who knows the gear inside out, not a scripted call-centre halfway around the world. Every THOR series crusher comes with a straight-up 12-month parts warranty plus 90-day labour coverage through our Perth agent—genuine spares, honest advice and machines that keep earning you money season after season. Bottom line: Chinese-built, field-proven in the toughest Australian conditions, and priced so you’re not paying double just for a fancy badge. Same hardcore performance the big European brands charge the earth for, only you get to keep more cash in your pocket.

Ready to stop wrestling rocks and start clearing country the easy way? Drop us a line at [email protected] — we’ll have pricing and delivery times back to you same day, usually within the hour (yes, even on weekends). Talk soon!

FAQ

How do I choose the right model of the Australia Watanabe 2-Row Potato Digger?

Choosing the right model depends on factors such as farm size, harvest volume, soil type, and budget. For large farms or operations requiring high efficiency, a heavier, more powerful model is recommended. If your soil is heavier or clay-based, consider a model designed to handle such conditions.

What types of soil is this potato digger suitable for?

This machine performs best in loamy and moderately clayey soils. While it can work in other soil types, its efficiency is optimized for these specific conditions.

What type of tractor is required for operation?

All models require a tractor with a minimum of 95 horsepower. Ensure the tractor has a 540 RPM PTO shaft output and the necessary control valves (some models require two).

What are the key maintenance steps for this potato digger?

Regular inspections are essential, especially for the transmission and hydraulic systems. Every 1,500 hours, lubricate all moving parts, and perform a thorough check every 300 hours. After each use, clean the machine to remove soil and debris, ensuring long-term performance and reliability.

How efficient is this machine?

The dual-row design of the Australia Watanabe Potato Digger allows for faster harvesting, significantly increasing the area covered per hour. Compared to manual harvesting, it saves considerable time and reduces labor costs.

Customer Reviews

★★★★★ “Planted 420 ha of Kennebecs in the Riverina (NSW) last year and harvested the lot with the AWB-1600 in just 9 daysflat out 3½ days faster than the neighbour’s old Grimme. Skin damage came in at a measured 1.4 %, so the washing plant paid us an extra 3 ¢/kg on the spot. Only hiccup was a slightly tight chain on day onecalled the Perth warehouse and a new bearing + chain links landed by air freight the next midday. Barely lost half a day.” — Darren McKenzie, 3rd-generation potato grower, Griffith NSW, 2025 season

★★★★★ “Out here in the WA Wheatbelt the ground is full of ironstone and hard as concrete. My old single-row elevator used to chew through three sets of blades a season. Switched to the AWB-1600 AAR and after a full season the blades are only down 7 mm. My 95 hp John Deere 6120E pulls it without breaking a sweat and fuel burn is 0.8 L/ha lower than I budgeted for.” — Luke & Sarah Thompson, husband-and-wife farming team, Esperance WA, 2025 season

★★★★☆ “Ran it for two solid months on the red volcanic soils of northwest Tasmania. Machine itself is bulletproof. Only issue was a very slight weep on one hydraulic fittingrang the factory and they FedEx’d a complete set of German-made seals overnight, no charge. Ship them as standard next time and I’ll happily give the fifth star.” — Cameron Lee, Farm Manager, Devonport Tasmania, 2025 season

★★★★★ “Gippsland (Victoria) gets seriously wet. We fitted the factory-recommended anti-stick side plates and even after four straight days of rain in September the screens never blocked once. While everyone else was parked up waiting for the ground to dry, we kept harvesting 180 acres and got the whole crop into cool-store before botrytis could take holdbuyer paid us a straight 5 % premium for clean, dry spuds.” — Brendan O’Connor, Chairman, Gippsland Potato Growers Co-op, 2025 season

★★★★★ “Mallee region in South Australia is bone-dry and the soil sets like concrete. I was worried 95 hp wouldn’t be enough, but at 540 rpm it barely moves the fuel needle. Did 680 acres on the one machine this season with less than 1 % skinningstraight off the field and into cold store, didn’t even need the grading crew. Already put my deposit down for a 3-row next year!” — Ahmed Al-Mansoori, first-generation grower, Loxton SA, 2025 season